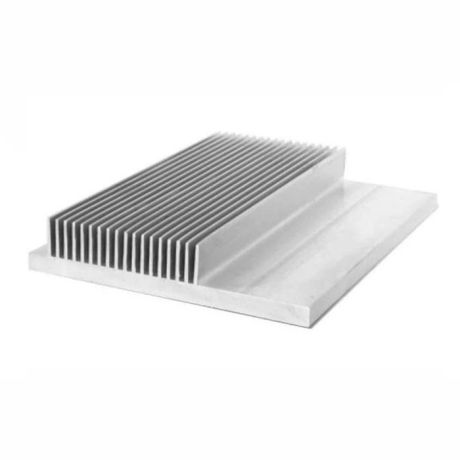

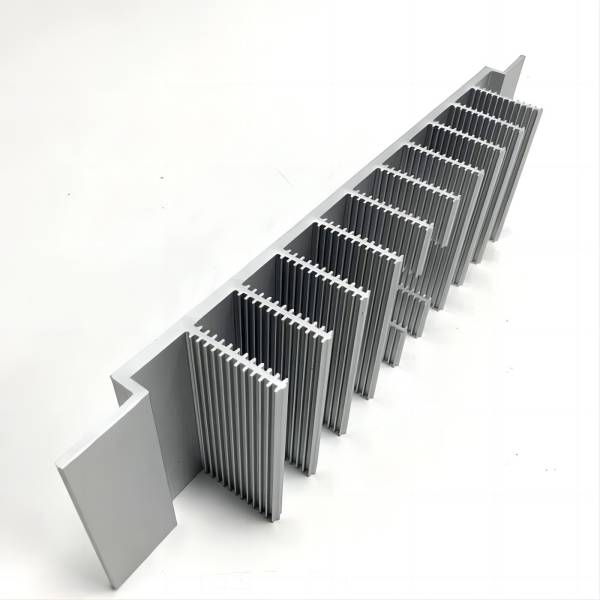

Led Light Heat Sink

The main function of the led light heat sink produced is to continuously export and dissipate the heat generated during the operation of the LED chip to the environment, so that the temperature of the chip is kept within the required range, so as to ensure that the LED lamp can work normally.

At present, the production technology of LED is gradually strengthening, and the issue of heat dissipation has always been a concern for LED manufacturers. Heat dissipation directly affects the service life of LED lighting fixtures.

Method to solve the heat dissipation of LED panel lights.

The heat dissipation problem of indoor lighting fixtures and LED panel lights. In LED panel lights, the chip converts 30% -35% of electrical energy into light energy during normal operation, and the other 65% -70% is converted into heat energy. LED panel lights are sensitive to temperature, and generally, only when the junction temperature is below 125 ℃ can LED avoid performance degradation or failure. 70% of LED failures come from excessive temperature, and the temperature increases every 20 ℃ when the load is at half of the rated power, The failure rate will double.

We can consider ways to solve the heat dissipation of LED panel lights from the following three aspects:

1. Improve the heat release characteristics of the radiator surface, such as installing multiple heat sinks on the surface and expanding the heat release area of the radiator.

2. The heat dissipation of LED panel lights should also consider eliminating factors that hinder heat transfer in the heat transfer path, such as expanding the cross-sectional area of the path (for example, thick copper wire is easier to conduct heat than thin copper wire), and applying thermal lubricant to ensure that there are no gaps in the connection parts of the product.

3. Because LED panel light is thin, fan or Natural convection heat dissipation method cannot be used for heat dissipation, so it can only be considered from the perspective of structure and materials. The aluminum frame used for LED panel lights is the main channel for heat dissipation, as aluminum has a faster thermal conductivity, which is beneficial for heat dissipation.

LED lighting applications and heat dissipation technology requirements are different, so that the LED lighting heat dissipation component industry presents different competitive characteristics. We always adhere to the talent view of "knowing others, and good ones", boldly cultivate and use all kinds of talents, and are committed to producing better LED heat sink.

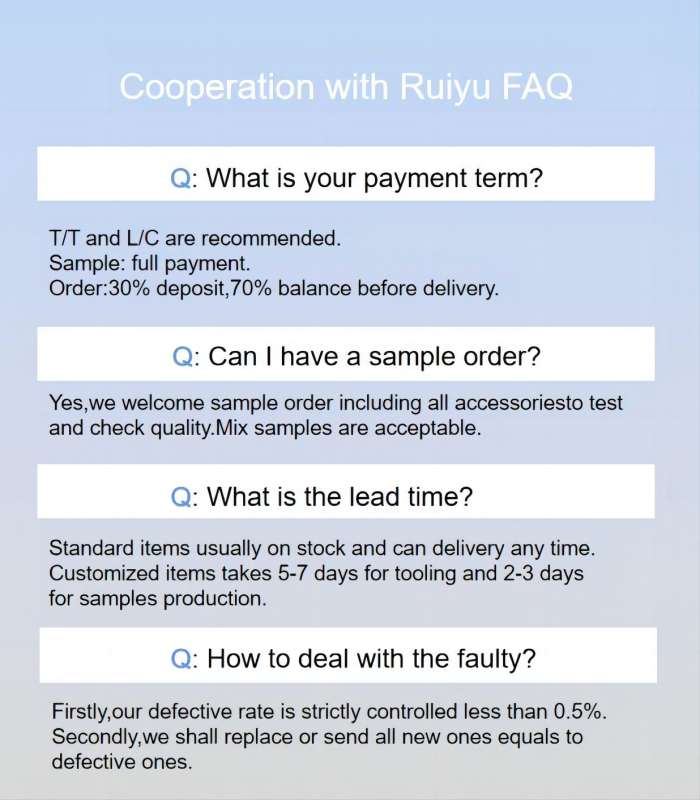

T/T and L/C at sight are recommended. Product name:Custom Aluminum Extrusion Mold Fee:Full pay before mass production. Order:30% deposit,70% balance before delivery or L/C at sight. Other Situation:Please feel free to contact us....more