Aluminum Heat Sink For High Power Amplifier

Aluminum is an excellent thermal conductor. Radiators made of aluminum have the advantages of high specific heat capacity and light weight.

Aluminum is an excellent thermal conductor. These radiators are made of aluminum, with high specific heat capacity and light weight. Aluminum heat sinks are typically used to dissipate the heat generated by high-power amplifiers.

The design of aluminum heat sinks for high-power amplifiers depends on the rated power of the amplifier, ambient temperature, and the capacity of the heat sink. The surface area of the radiator affects the heat dissipation effect.

A radiator is composed of heat dissipation fins. The heat sink is usually serrated, which can increase the surface area. The heat generated by the amplifier is transferred to the radiator through the installation surface. The radiator absorbs this heat and dissipates it into the air through the fins.

Aluminum heat sink for high-power amplifiers, used in high-power electronic products such as amplifiers and power supplies.

Product Description

Product Name | Aluminum Heat Sink For High Power Amplifier |

Material | Aluminum Alloy 6000 series, such as 6005, 6061, 6063, 6082etc. |

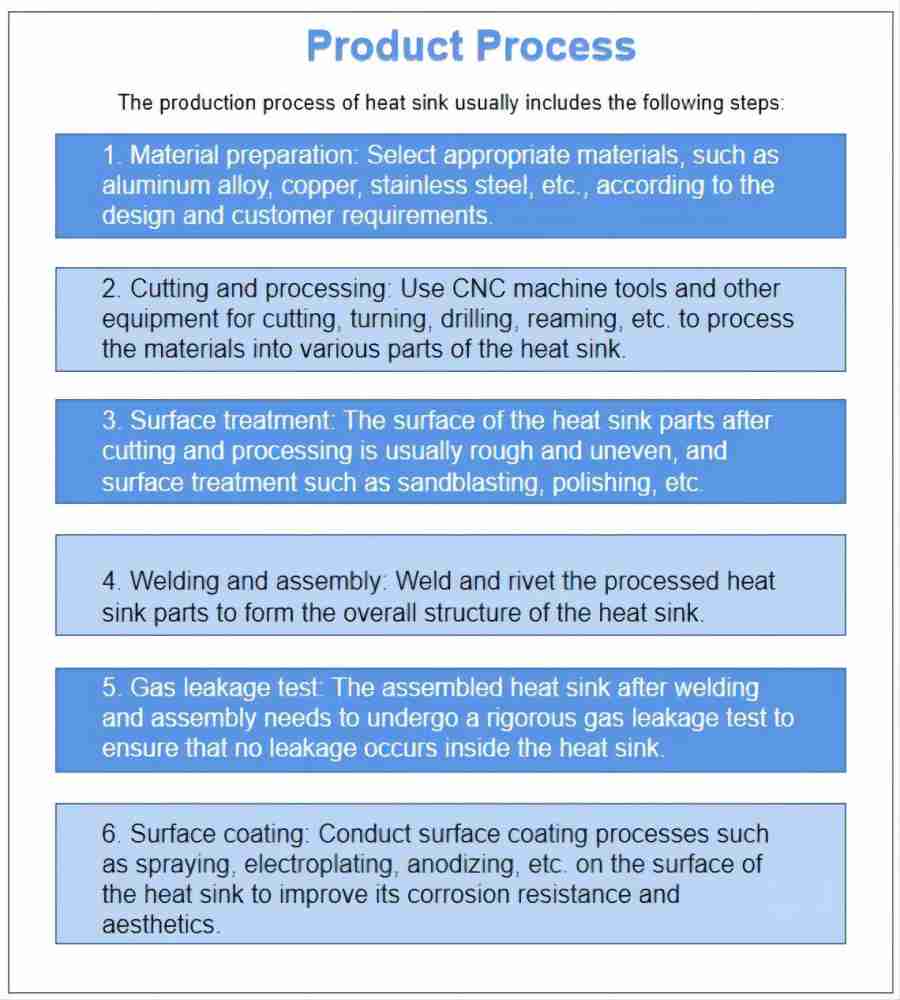

Surface Treatment | Polishing, Sandblasting, Anodizing, Powder Coating, Electroplating, Zinc Plating, Silk-screen |

Process | CNC Machining (Turning, Milling, Drilling) |

Quality Control | 100% checking before ship |

Guarantee | Surface color can be stable for 10~20 years indoor using |

Our Advantage | Superior in Quality, Reasonable in Price and Deliver On Time |

Packaging | Wood case or carton box, l With plastic bag,with pearl-cotton package. l To be packed in cartons or wood case. l Use glues tape to seal cartons.or pin tight the wood case with nail. l Deliver out by DHL,FEDEX. Or according to customers' requirement. |

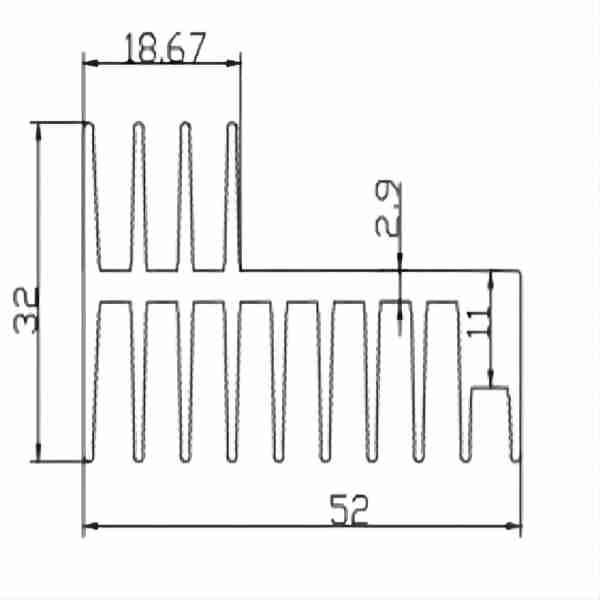

Product Dimension

Product Advantages

1. Pure aluminum, high heat transfer coefficient.

2. Heat transfer directly to the fins without through thermal resistance.

3. Patent forging base plate riveting technology, instead of tin welding process, large extrusion aluminum, and large die-casting.

4. Fins resist torsion and drawing force, stable process.

5. Can be radiated and local arrangement fins, heterogeneous-material combination.

6. Can be combined with heat pipe, improve heat dissipation performance.

7. High power process.

8. For passive cooling and large area of heat radiator.

9. Stamping forming, mass production.

10.light weight.

The production process of the heat sink requires fine, patient and precise operation, high machining accuracy, strict work procedures, and the quality of the heat sink needs to be monitored and controlled through various inspection methods.

In summary, an aluminum heat sink is a popular choice for dissipating the heat generated by high-power amplifiers due to its excellent heat conductivity, specific heat capacity, and lightweight. The design of an aluminum heat sink depends on the power rating of the amplifier, the ambient temperature, and available space. Both passive and active cooling mechanisms are used in aluminum heat sinks for high-power amplifiers.

T/T and L/C at sight are recommended. Product name:Custom Aluminum Extrusion Mold Fee:Full pay before mass production. Order:30% deposit,70% balance before delivery or L/C at sight. Other Situation:Please feel free to contact us....more