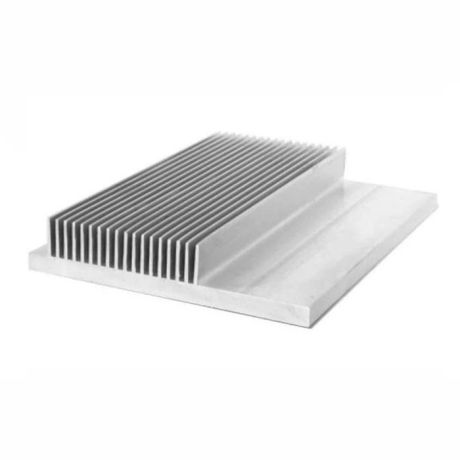

Industrial Heat Sink

customized aluminium heat sink manufacturers

we have many heatsink molds, giving you more choices, saving you mold costs.

welcome customized dimensions

Industrial heat sinks are devices used to dissipate heat generated by industrial processes and products. Heat sinks are necessary in order to keep these processes and products from overheating, which can lead to significant damage. The difficulty of producing an industrial heat sink depends on the complexity of the design and the material used. Simple designs can be made from aluminum, but more complex designs may require more advanced materials such as copper, titanium, and even carbon fiber. These materials may require more expensive manufacturing processes and higher quality control standards, making them more difficult to produce.

Product Information

Product Name | Industrial Heat Sink |

| Material | Aluminum Alloy, Steel, Copper, Brass, Plastic, etc |

| Surface Treatment | Polishing, Sandblasting, Anodizing, Powder Coating, Electroplating, Zinc Plating, Silk-screen |

| Process | CNC Machining (Turning, Milling, Drilling) |

| Quality Control | 100% checking before ship |

| Tolerance | +-0.01 mm |

| Our Advantage | Superior in Quality, Reasonable in Price and Deliver On Time |

| Packaging | Wood case or carton box,

Or according to customers' requirement. |

Application

Industrial radiators are widely used in industries such as computers, electronics, aerospace, automobiles, and healthcare. Radiators are necessary in these industries, as they can prevent products from overheating and maintain safe and efficient operation. The radiator can also enable the passing components to operate at lower temperatures, helping to improve the durability and reliability of the product.

Aluminum alloy industrial radiators have the advantages of beautiful appearance, light weight, good heat dissipation performance, and good energy-saving effect.

Aluminum alloy industrial radiators can be customized according to customer needs. Generally, 6063 aluminum alloy is used, and we have advanced equipment and mature technology to ensure the cutting accuracy, excellent size, stable structure, and excellent heat dissipation performance of radiator products; There are also various surface treatment processes, such as sandblasting, wire drawing, anodizing, sandblasting, etc., to make the heat dissipation device beautiful, durable, and decorative, achieving personalized needs.

T/T and L/C at sight are recommended. Product name:Custom Aluminum Extrusion Mold Fee:Full pay before mass production. Order:30% deposit,70% balance before delivery or L/C at sight. Other Situation:Please feel free to contact us....more