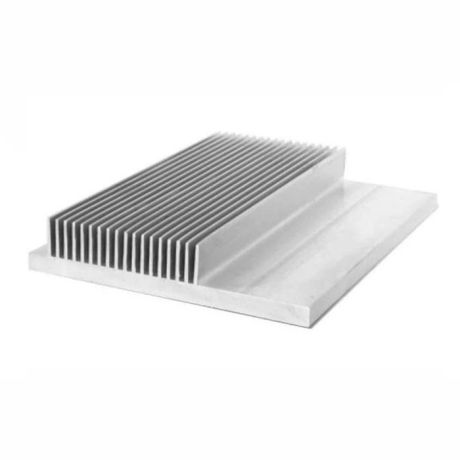

Extruded Heatsinks With CNC Machining

In the production process of aluminum profile radiators, CNC machining is required after cutting the aluminum profile into semi-finished products. CNC machining is a more refined operation. There are many issues that need to be noted during the operation process.

The heat sinks processed by CNC are widely used, such as in video servers, adapters, optical transceivers, routers, controllers, car shell CPS/CPRS shell, jammer shell, inverter shell, CPU heat sink shell, power supply shell, electronic communication, power communication, medical equipment, and controller chassis, etc. The size can be customized by any mold. Currently, most heat sinks on the market are composed of aluminum heat sinks, And some heat dissipation fins have insufficient heat dissipation during the heat dissipation process, and the heat dissipation efficiency of the fins cannot be maximized. The fins adopt a rectangular shape, with a small total heat dissipation area. The heat cannot be dissipated in a timely manner, resulting in accumulation, weakened heat dissipation effect, and even damage to the radiator in severe cases.

A type of CNC processed heat sink, with several through holes symmetrically arranged on both sides of the heat dissipation plate, several heat dissipation fins on one side of the through holes, and several protrusions uniformly arranged on the outer wall of the heat dissipation fins. A heat transfer plate is arranged on one side of the heat dissipation fin, and a threaded groove is symmetrically arranged on both sides of the heat transfer plate. The screw connection between the heat dissipation plate and the heat dissipation plate runs through the threaded groove and the through hole, and the screw is connected with a nut located on one side of the heat dissipation plate, The side of the heat transfer plate near the heat transfer plate is equipped with grooves 1 and 2, and the heat transfer plate is connected to the heat transfer plate through components 1 and 2.

Specification Of Extruded Heatsinks With CNC Machining

Product Name | Extruded Heatsinks With CNC Machining |

Dimension | customized |

Shape | with standard and customized sizes |

Samples | Available |

Sample Leadtime | about 10 Days |

Color | Normal Color(silver/black/steel gray),Customized Color |

Machining | Precision Cutting up to ±0.5 mm by Customized size |

Finished | Anodized, Minimum 12 um thickness |

Surface Treatment Optional | Mill, Anodizing, Powder coating, Electrophoresis, Polished and Brushe, Galvanized ,Fluorocarbon Coating |

Tolerance | Extrusion: ±0.01 mm |

| Deep Processing | Fine cutting ,Drilling ,Tapping ,Mechanical polishing ,etc |

| OEM | Available |

| Application | Electronic Industry |

Precautions Description

The characteristics of CNC heatsinks include:

1. Precision: CNC machines are able to create heatsinks with extremely precise dimensions, allowing for optimal heat dissipation.

2. Durability: CNC heatsinks are typically made from high-quality materials, such as aluminum or copper, which are durable and long-lasting.

3. Flexibility: CNC machines can be programmed to create heatsinks in a variety of shapes and sizes, making them suitable for a wide range of applications.

4. Efficiency: CNC heatsinks are designed to maximize the surface area available for heat dissipation, ensuring efficient cooling performance.

5. Customization: CNC machines can be used to create custom heatsinks that are tailored to specific applications, allowing for maximum performance and efficiency.

Application Scenior

The surface of the extruded radiator can also undergo anodizing treatment to improve the corrosion resistance, wear resistance, and appearance of aluminum. The most commonly used types of extruded aluminum heat sinks in China include electronic heat sinks, computer heat sinks, sunflower heat sinks, and power semiconductor heat sinks. Due to its superior performance, extruded aluminum radiators are widely used in machinery, automobiles, wind power, engineering machinery, air compressors, Locomotive, household appliances and other industries.

T/T and L/C at sight are recommended. Product name:Custom Aluminum Extrusion Mold Fee:Full pay before mass production. Order:30% deposit,70% balance before delivery or L/C at sight. Other Situation:Please feel free to contact us....more