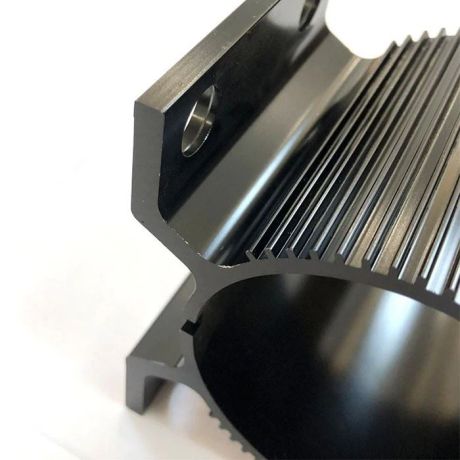

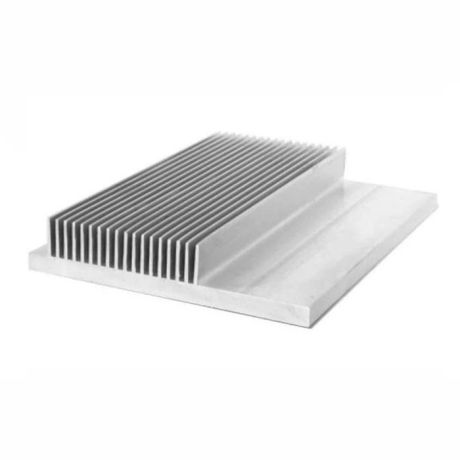

Engine Heat Sink

The engine heat sink is usually made of 6060 aluminum profile, because the 6063 aluminum profile heat sink has a low density and is easier to process into other parts, simple installation and convenient maintenance.

Engine Heat Sink design requirement

The design of the radiator should meet the heat dissipation requirements of the engine within its normal operating range, while also considering the minimum space required for vehicle installation and maintenance convenience.

(1) The heat dissipation capacity can meet the needs of the engine under various working conditions;

(2) The cooling system consumes low power and has fast heat engine;

(3) Small size, light weight, easy to disassemble and repair;

(4) Reliable use, long service life, and low manufacturing cost.

Engine heat sinks are an important component of any engine, as they help to dissipate heat and keep the engine running at optimal temperatures. Heat sinks are typically made of aluminum or copper and are designed to absorb and dissipate heat away from the engine. Heat sinks are usually attached to the engine block or cylinder head, and they are often used in conjunction with a fan or other cooling system.

Heat sinks are essential for keeping an engine running at its best. Without a heat sink, the engine would overheat and eventually fail. Heat sinks help to keep the engine running at a safe temperature, and they also help to reduce the amount of noise generated by the engine.

Heat sinks are also important for improving the performance of an engine. By dissipating heat away from the engine, the engine can run more efficiently and produce more power. Heat sinks also help to reduce the amount of fuel consumed by the engine, which can help to reduce emissions and improve fuel economy.

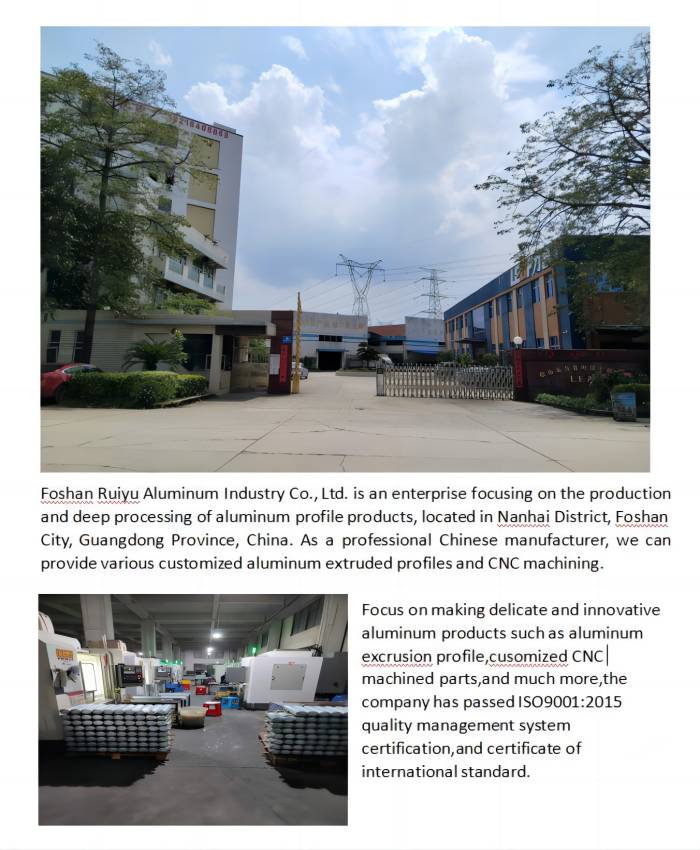

T/T and L/C at sight are recommended. Product name:Custom Aluminum Extrusion Mold Fee:Full pay before mass production. Order:30% deposit,70% balance before delivery or L/C at sight. Other Situation:Please feel free to contact us....more