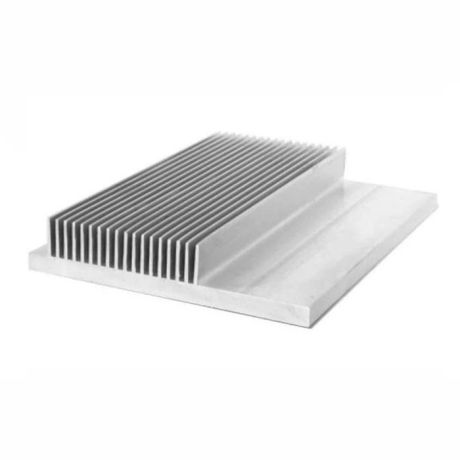

CNC Heat Sink

The heat sinks processed by CNC are widely used, such as in video servers, adapters, optical terminals, routers, controllers, jammer shells, inverter shells, CPU heat sink shells, power supply shells, electronic communication, power communication, medical equipment, and controller cases

CNC (computer numerical control) heatsinks are a type of heat sink that are machined using automated CNC machines. These heatsinks are typically used to dissipate heat from electronic components, such as CPUs and graphics cards.

During the production of aluminum profile heat sink, after cutting the aluminum profile into semi-finished products, CNC processing will be carried out. CNC processing is a more refined operation. There are many problems in the operation process that should be paid attention to. If it is not handled Good will result in a higher failure rate of aluminum heat sink. So what should we pay attention to when processing CNC heat sink? What are the precautions?

Precautions for CNC Heat Sink Processing

1.The tool material has good toughness and low hardness, which is suitable for rough machining. The tool material has poor toughness and high hardness and is suitable for finishing. Be careful not to touch the gears of the aluminum heat sink during the processing, so as not to damage the gears, especially if some heat sink have been processed with anodes, special attention is required.

2. If the CNC heat sink is too high, especially when processing some high-power heat sink, you should use different lengths of knife to roughen it in layers. After roughing with a big knife, you should use a small knife to remove the remaining material.

3. Use flat-bottomed knives to process planes, and use less ball knives in order to reduce processing time; if there is an inclination and it is an integer, use an inclination knife to process. Set tolerances reasonably to balance the machining accuracy and computer calculation time. Do more procedures to reduce the time of empty tools.

4. If the material hardness of the aluminum profile heat sink is high, choose up-cut milling; if the material hardness of the aluminum profile heat sink is low, choose down milling. In addition, roughing up milling, finishing down milling.

The precautions for CNC heat sink processing are shared here for everyone. The heat sink we are familiar with are some of the current electronic products, such as computers, air conditioners, refrigerators, etc., as well as some more electronic products. As used in the heat sink, CNC heat sink is also extremely important in modern society, providing more possibilities for our production.

Advantages of CNC radiator processing:

1. In the case of multiple varieties and small batch production, the production efficiency is higher, which can reduce the time for production preparation, machine tool adjustment, and process inspection. Moreover, the cutting time is reduced due to the use of the optimal cutting quantity.

2. Rough machining allowance is large, cutting amount is large, and machine tools with high power, good stiffness, high efficiency, and low accuracy can be used. Precision machining has low cutting force and minimal damage to the machine tool, so high-precision machine tools are used. This brings into play the respective characteristics of the equipment, which can not only improve productivity but also extend the use of precision equipment.

3. During rough machining of CNC heat sinks, the metal layer cut is thicker, resulting in greater cutting and tightening forces, as well as higher cutting temperatures, which can cause significant deformation. According to the machining stage, the machining errors caused by rough machining can be corrected through semi precision machining and precision machining to ensure the machining quality of the parts.

4. CNC is a multi axis linkage device, especially a four axis and five axis device, which can process complex surfaces, curved steps, and even some unobservable processing parts that are difficult to process using conventional methods.

T/T and L/C at sight are recommended. Product name:Custom Aluminum Extrusion Mold Fee:Full pay before mass production. Order:30% deposit,70% balance before delivery or L/C at sight. Other Situation:Please feel free to contact us....more