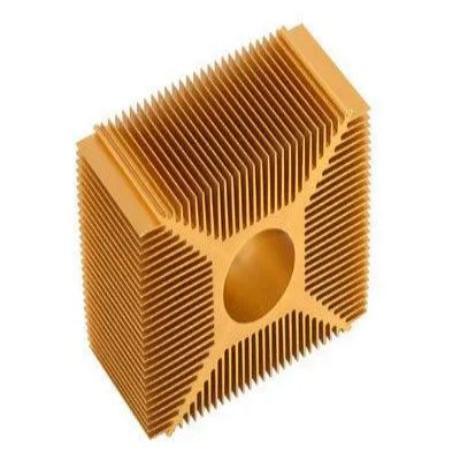

Anodized Heat Sink

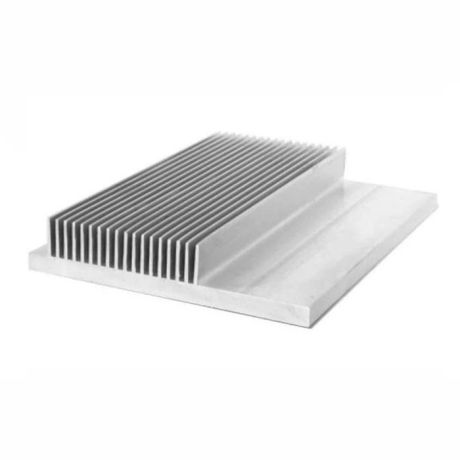

Aluminum has a soft texture and poor corrosion resistance, so necessary surface treatment is required for aluminum profile radiators. Anodizing is a common surface treatment method.

The surface anodizing treatment of aluminum profile heat sink is a widely used surface treatment technology of aluminum profile heat sink. The corrosion resistance and abrasive resistance performance are significantly improved, not only the quality is better in use, but also the aesthetics are greatly improved.

Specification

| Material | Aluminum 6063 / 6061 |

| Color | Mill Finished |

| Surface Treatment | Mill finish, powder coated, anodized, electrophoresis, Polishing |

| Deep Process | Precise cutting, drilling, milling, fabricating |

| Length | Custom Available |

Anodized Heat Sink Model

Anodizing usually refers to sulfuric acid anodic oxidation, which is the process of forming an oxide film on aluminum products (anode) under the corresponding electrolyte and specific process conditions due to the action of external current. This oxide film makes aluminum The surface hardness and wear resistance of the alloy have been improved, thereby expanding the application range and prolonging the service life of the aluminum profile heat sink.

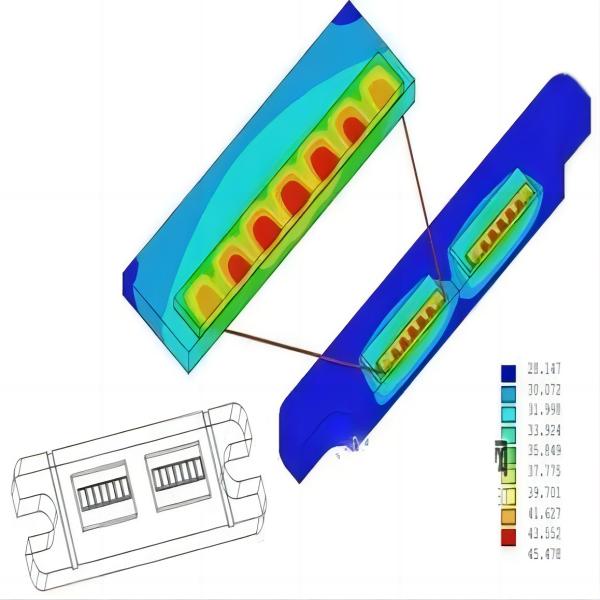

In addition, the color of the aluminum profile heat sink will turn black after anodizing, so anodizing is also called black anode, or black oxidation. The anodic oxidation of the aluminum heat sink can also increase the aesthetics of the product. Many electronic product substrate boxes are black, and the black heat sink can form a uniform tone and increase the aesthetics. Some customers' water-cooled plate heat sinks will also undergo anodic surface treatment, especially for water-cooled plates on optical instruments such as lasers.

Benefits of Aluminum Profile Heatsink anodizing

Taking the aluminum profile heat sink as an example, the electrochemical method can be used to form a dense high-quality oxide film on the surface of aluminum or aluminum alloy), which is difficult to be thicker, and its thickness can reach tens to hundreds of microns, which can effectively Improves the corrosion resistance of aluminum. This electrochemical process of oxidizing the surface of aluminum is called anodizing of aluminum.

Customized Anodization Colors

Therefore, the aluminum profile heat sink generally needs to be oxidized, but it mainly depends on the actual needs of the customer's products.

T/T and L/C at sight are recommended. Product name:Custom Aluminum Extrusion Mold Fee:Full pay before mass production. Order:30% deposit,70% balance before delivery or L/C at sight. Other Situation:Please feel free to contact us....more