Aluminum Radiator Profile

Brand RUIYU

Product origin Foshan

Aluminum Radiator Profile application scenarios is mainly applied in industries or products like LED Light,PCB,TEC ,Electronic,Laser Equipment ,IGBT,DC/DC Power,Telecom etc.

How do aluminum radiator profiles dissipate heat?

Aluminum radiator profiles are made of aluminum alloy and are commonly used for heat exchangers in engines and heating systems. Aluminum alloy has the characteristics of light weight and corrosion resistance. The aluminum radiator is designed to transfer heat from the engine coolant to the air passing through the coolant, in order to reduce the engine temperature.

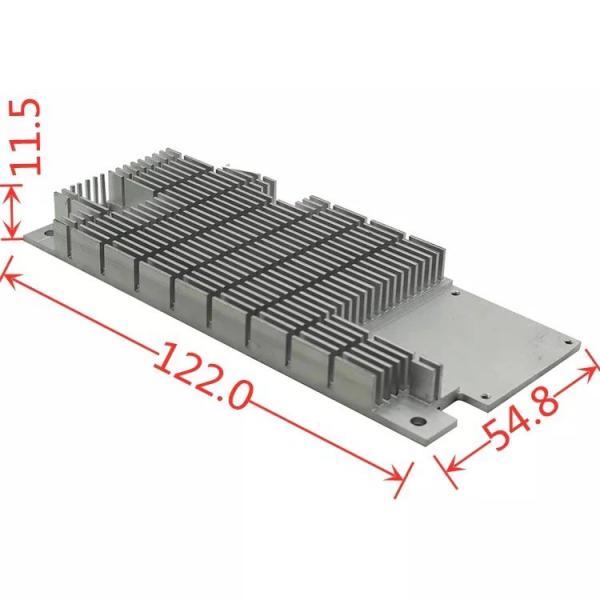

Aluminum radiator profiles typically consist of two parts: the thermal conductive plane (also known as the substrate) of the fixed equipment and the teeth. The materials used are mainly aluminum and aluminum alloys.

Specification

| Product Name | Aluminum Radiator Profile |

| Item | Aluminum Radiator Profile |

| Material | Aluminum 6063 |

| Size | Customized |

| Process | Aluminum Extruded+CNC Machining |

| Surface Treatment | Black Anodise,Clean,Polish ,Powder Coating ,Sand-Blasting,Nickel Plating Available |

Application

Aluminum Radiator Profile application scenarios is mainly applied in industries or products like LED Light,PCB,TEC ,Electronic,Laser Equipment ,IGBT,DC/DC Power,Telecom etc.

Technology for producing aluminum radiators:

The steps for making aluminum radiator profiles. Firstly, a hydraulic press will be used to extrude the aluminum alloy melted billet into a long and straight profile. Then, the profile is cut and heat treated to improve its strength and corrosion resistance.

Secondly,Fabricate the radiator core by constructing alternating layers of aluminum radiator profiles and fins made of aluminum.

Then assemble the radiator core into a shell that includes the bottom water tank, top water tank, and side water tank. The water tank is welded to the radiator core. Finally, pressure test the completed aluminum radiator profile to ensure there are no leaks.

In summary, aluminum radiator profiles have become important components in many heat exchange applications due to their lightweight and corrosion-resistant properties. The production process includes several steps from melting aluminum to assembly, producing high-quality products for customers that are durable, efficient in heat transfer.

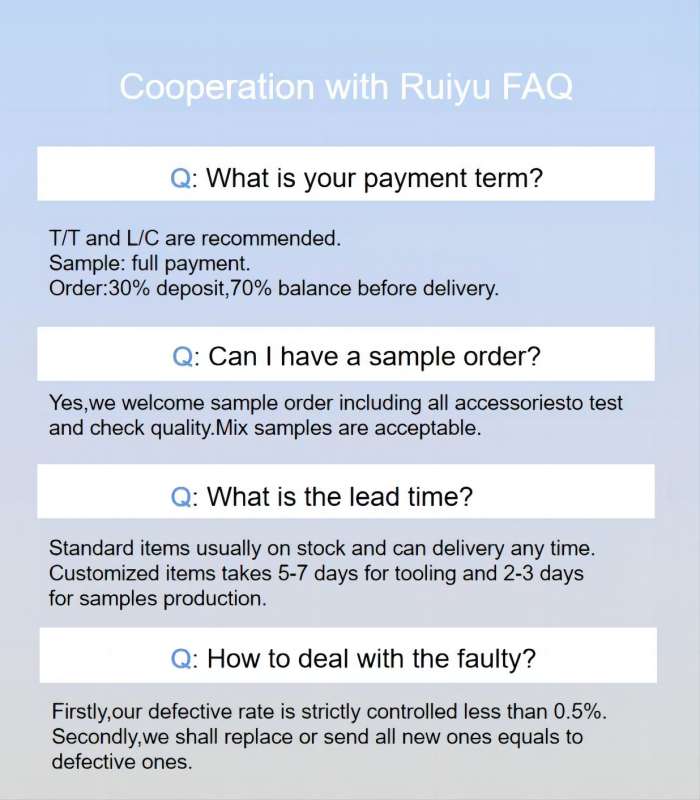

T/T and L/C at sight are recommended. Product name:Custom Aluminum Extrusion Mold Fee:Full pay before mass production. Order:30% deposit,70% balance before delivery or L/C at sight. Other Situation:Please feel free to contact us....more