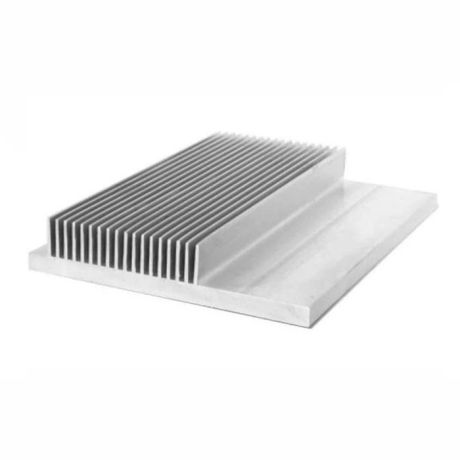

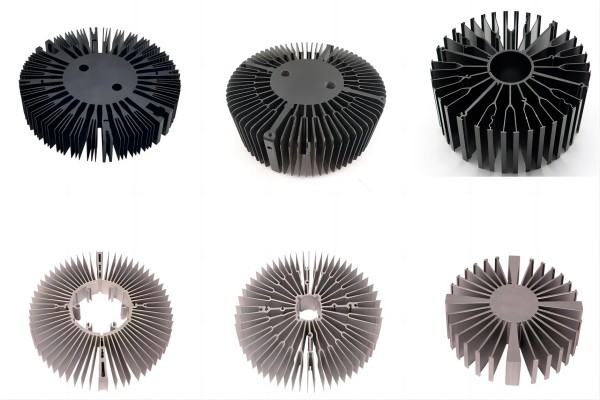

Aluminum Led Bulb Heat Sink

A LED bulb heat sink is an essential component of LED lighting systems. It is a device that absorbs and dissipates heat generated by the LED bulb.

A LED bulb heat sink is a device that is used to remove and dissipate excess heat created by a LED light bulb, thus making it more efficient and longer lasting. It is made up of a metal or aluminum material, which is intended to quickly absorb and transfer thermal energy, away from the light bulb, into the air. The basic heat sink design is composed of a heat conducting body fitted into a set of fins. The design of the fins is determined by factors such as the amount of thermal energy to be dissipated, and the overall size of the heat sink.

Features:

Increased efficiency and long lifespan for LED light bulbs

- High thermal conductivity materials like metals or aluminum

- Makes LED light bulbs more efficient by dissipating heat quickly

- Design of fins determines thermal energy to be dissipated and overall size

- Lightweight and cost-effective

Moreover, the cost of mold opening of this aluminum profile is not cheap, and it is recommended to consider opening mold customization for mass distribution.

Production Process

Step 1: Design - The manufacturer first designs a heat sink to maximize the transfer of heat from the LED bulb to the heat sink, taking into account factors such as size and weight, as well as any special requirements.

Step 2: Material Selection - Manufacturers choose materials that are sturdy, lightweight, and have high thermal conductivity, such as aluminum or copper or a combination of copper and aluminum.

Step 3: Machining - Use various techniques such as CNC machining, milling, and turning to machine the selected material.

Step 4: Fin Forming - Use a dedicated machine to shape the fins to maximize airflow and heat dissipation

Step 5: Assembly - Weld the radiator and heat sink together to obtain a device that can effectively dissipate the heat energy of LED bulbs.

Step 6: Testing - Factory test the completed equipment to ensure optimal performance

T/T and L/C at sight are recommended. Product name:Custom Aluminum Extrusion Mold Fee:Full pay before mass production. Order:30% deposit,70% balance before delivery or L/C at sight. Other Situation:Please feel free to contact us....more