The difference between aluminum alloy profile 6061 and 6063

1.The Difference in Chemical Composition

| Si | Fe | Cu | Mn | Mg | Zn | Ti | Cr | |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.25 | 0.15 | 0.04-0.35 |

| 6063 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.1 | 0.1 | 0.1 |

6 series aluminum alloy is a medium-strength heat-treatable strengthened alloy. Mg plays a significant role in strengthening aluminum alloys, and Zn and Cu also play a significant role in strengthening aluminum alloys.

As can be seen from the table above, 6061 aluminum alloy profile has more alloying elements than 6063 aluminum alloy profile. Judging from the Mg and Si content, 6061 aluminum alloy profile is about 30~50% more than 6063 aluminum alloy profile. The most direct impact is that the strengthening effect of 6061 aluminum alloy profile is greater than that of 6063 aluminum alloy profile.

2.Differences In Mechanical Properties

| Material | MPa | MPa | HB |

6061-T6 | 310 | 275 | 95 |

6063-T5 | 185 | 145 | 60 |

6063-T6 | 230 | 180 | 70 |

We can see from the chemical composition that the trace element content of 6061 aluminum profiles is higher than that of 6063 aluminum profiles. As a 6 series alloy with Mg and Si as the main elements, Mg and Si form the strengthening phase Mg2Si. The higher the Mg and Si content, the greater the amount of Mg2Si, and the greater the heat treatment strengthening effect.

In contrast, the higher the tensile strength, the greater the deformation resistance, so the plasticity of the aluminum alloy will decrease.

Therefore, according to the design value of tensile strength, T5 profiles should appropriately fine-tune the Mg and Si content to reduce the tensile strength to obtain better plasticity, especially for profiles with complex cross-sections.

3. Comparison Of Plasticity

6061-T6 aluminum profiles is used where a certain strength and hardness are required. 6063 aluminum profiles is a representative alloy for extrusion and has good extrudability.

Especially 6063-T5 aluminum profiles has excellent thermoplasticity and can be extruded at high speed into various profiles with complex structures (such as thin-walled, hollow) or forged into forgings with complex structures. It has a wide quenching temperature range, low quenching sensitivity, and is easy to extrusion. After demoulding and forging, as long as the temperature is higher than the quenching temperature. It can be quenched by spraying water or water penetration.

4.Other Comparisons

Surface treatment: Both 6061 aluminum alloy and 6063 aluminum alloy have good oxidation properties. The surface adhesion of 6063 aluminum alloy is slightly higher than that of 6061 aluminum alloy, so it has extremely strong oxidation ability.

Cutting properties: Overall good, 6061 aluminum alloy profiles is better.

Corrosion resistance: Generally good, 6063 aluminum alloy profiles is better.

Weldability: All can be welded, 6063 aluminum alloy profiles is better.

Price: The prices of the two are about the same. Currently, 6063 aluminum alloy profiles is slightly more expensiv

5. Comprehensive summary

In general, the advantage of 6061 aluminum alloy is strength, while the advantage of 6063 aluminum alloy is extrusion shape; you can choose the one that is most suitable for the product based on its performance characteristics.

6061-T6 aluminum alloy is used where a certain strength and hardness are required.

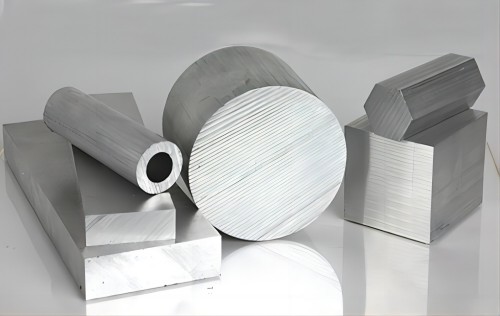

The main forms are generally plates, bars,and profiles with uncomplicated cross sections.

6063-T6 aluminum alloy is used in situations where the strength is not so high.

The main form is generally plates and rods.

The main form of 6063-T5 aluminum alloy is extruded profiles of various shapes.

Commonly used in building aluminum alloy doors and windows, curtain walls, and industrial frame structures.