Aluminum Extrusion For Photovoltaics:Design and selection

According to a report from a market research institution, the global photovoltaic solar panel market reached approximately US$180 billion in 2020 and is expected to grow to approximately US$250 billion by 2026, with a compound annual growth rate of approximately 5%. This growth trend mainly benefits from the rising global demand for green energy and the continuous innovation of photovoltaic technology.

In the photovoltaic solar panel market, aluminum profiles are widely used and indispensable. According to statistics, the demand for aluminum profiles in fields such as photovoltaic module frames, photovoltaic bracket systems and photovoltaic trackers accounts for nearly 70% of the total demand for photovoltaic solar panels. This fully reflects the key position of aluminum profiles in the photovoltaic solar panel market.

The installed base will be divided into large solar farms, residential and commercial rooftops, and a smaller number of mobile solar panels on top of cars and trucks.

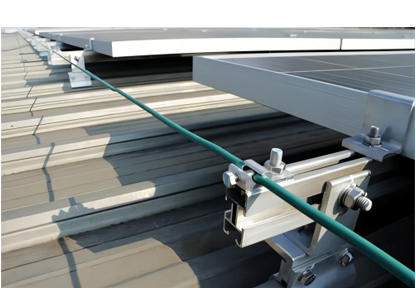

However, in all these applications, the success of photovoltaic relies on the use of aluminum building components for fixed and mobile structures.

Here, we discuss the pros and cons of aluminum profile in solar industry applications, as well as some design considerations for framing systems.

Table of Contents The Difference Between Aluminum and Steel for Solar Panel Frames Aluminum Frame Design Considerations The Benefits of Choosing Aluminum Profile Frames What Are The Disadvantages How to Choose Aluminum Alloy |

The Difference Between Aluminum and Steel for Solar Panel Frames

The solar panel frame is an important part of the photovoltaic solar panel. Its main function is to protect and support the solar cells. When it comes to frame material selection, aluminum and steel are two common choices.

First of all, although steel has high strength and hardness, it is heavy and requires high transportation and installation costs.

Making longer steel profiles requires welding the parts together, which is an additional manufacturing expense.

Moreover, steel is prone to rust in humid environments, resulting in reduced service life.

The use of aluminum profiles has the characteristics of lightweight, good corrosion resistance, and easy processing, making aluminum profiles dominate the application in the photovoltaic solar panel market. The demand for aluminum profiles in fields such as photovoltaic module frames, photovoltaic bracket systems and photovoltaic trackers accounts for nearly 70% of the total demand for photovoltaic solar panels.

All things considered, aluminum profiles have shown obvious advantages in applications in the photovoltaic solar panel market and have become the preferred material for solar panel frames.

Aluminum Frame Design Considerations

In the design of aluminum frame for solar photovoltaic panels, there are several considerations that we need to pay attention to.

First of all, since photovoltaic panels need to withstand a certain amount of wind and snow pressure, do they have sufficient strength and stability?

Secondly, in order to ensure that the installation and maintenance of photovoltaic panels are convenient, should the design of the frame consider whether it is fixed or mobile, and is it easy to disassemble and assemble?

Finally, could it be exposed to salt water spray or other environmental contaminants?

All of these challenges can be overcome through careful design and use of the right aluminum alloys. Here are some of the benefits of using aluminum profiles to install solar panels.

The Benefits Of Choosing Aluminum Profile Frames

First, Aluminum Extrusion solar panel frame are easy to machine and customize. This means that different photovoltaic panel sizes and shapes can be designed for optimal solar collection.

Secondly, Aluminum Extrusion solar panel frame are naturally resistant to corrosion and form a hard layer of aluminum oxide when exposed to oxygen, which helps stop further corrosion.

Third, the Aluminum Extrusion solar panel frame has good thermal conductivity and can effectively transfer the heat generated by the photovoltaic panels to the surrounding environment, thereby reducing the operating temperature of the photovoltaic panels and improving solar energy conversion efficiency.

Finally, extrusions are ideal for modular installations that can be easily connected with fasteners and also allow for the necessary thermal expansion and contraction of heating and cooling cycles in outdoor environments.

What Are The Disadvantages

Although aluminum Extrusion frames for solar photovoltaic panels offer many advantages, there are also some disadvantages.

First, although aluminum has good corrosion resistance, aluminum solar panel frame may be corroded in certain extreme environments, such as high salt spray and acid-alkaline environments.

Secondly, the processing and customization of aluminum solar panel frames requires a high level of technology, which may result in higher production costs. In addition, although aluminum solar panel frames can improve the stability of photovoltaic panels, their heavy weight may affect the installation and transportation of photovoltaic panels.

Finally, although the thermal conductivity of the aluminum solar panel frame is beneficial to reducing the operating temperature of the photovoltaic panels, in low-temperature environments in winter, the thermal conductivity may cause the surface of the photovoltaic panels to freeze, affecting the solar energy collection effect.

Therefore, when selecting an aluminum solar panel frame for solar photovoltaic panels, comprehensive considerations need to be made based on the specific application environment and requirements.

How To Choose Aluminum Alloy

When selecting an aluminum alloy frame for photovoltaic solar panels, there are many factors to consider, such as strength, corrosion resistance, thermal conductivity, processability, etc. There is no perfect answer to what is the best aluminum alloy.

But there are a few good options:

Aluminum alloy 6063: This aluminum alloy is the cheapest. 6063 aluminum alloy is easily extruded, has good processability, and has an optimal surface finish. 6063 aluminum alloy is well known for its chemical and mechanical properties and is used in photovoltaic solar panel frames with complex shapes and demanding appearance.

Aluminum alloy 6061: The cost is slightly higher and the strength is higher than 6063 aluminum alloy, but it is more difficult to extrude. Suitable for large photovoltaic solar panel frames.

Aluminum Alloy 6005A:This is one of the new alloys with many beneficial properties. 6005A aluminum alloy has high strength and hardness and is suitable for photovoltaic solar panel frames that require larger loads.

In summary, solar photovoltaic panel aluminum frames are an important solution that can improve the overall performance and reliability of your solar system. When selecting an aluminum alloy frame for photovoltaic solar panels, the selection should be based on the specific application environment and requirements to achieve the best photovoltaic solar panel performance and reliability. This article introduces the design considerations, advantages and disadvantages of aluminum profiles for photovoltaic use and how to choose aluminum alloy frames. It is hoped that it can provide a useful reference for the material selection and design of solar photovoltaic panels.

Due to the unique nature of the extrusion process, developers are advised to work closely with manufacturers to optimize their manufacturing designs. If you have questions about how aluminum profiles can benefit you, Ruiyu’s experts are here to offer their expertise. Contact us today.