Cold Forging Aluminum Parts

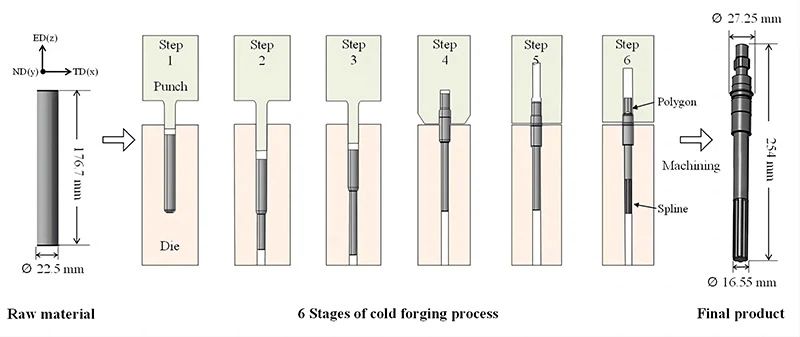

Cold forging technology is one of the new processes that have developed rapidly in all industries in recent years, and it is also an important means in the processing of product parts.

Cold forging is a manufacturing process that involves the shaping of metal parts through the application of pressure, typically at room temperature. The process is used to create small to medium-sized components used in a variety of industries, from automotive and aerospace to consumer goods.

Features of cold forging technology :

1. High precision: Cold forging technology allows for the creation of highly precise metal parts with tight tolerances and complex geometries.

2. High strength and durability: Cold forged parts have greater strength and durability compared to parts created through other manufacturing processes.

3. Cost-effective: Cold forging technology enables fast production rates and high material utilization rates, resulting in overall cost savings.

4. Reduced waste: Cold forging technology produces less waste compared to other manufacturing processes, resulting in a more sustainable production process.

5. Good surface finish: Cold forging technology produces parts with a smooth and even surface finish, reducing the need for additional processing or finishing.

Advantage of Cold Forging Aluminum Parts

1. Less material consumption and basically no waste. The cost of materials is thus saved. And it will not pollute the environment due to unstable bad materials;

2. High production efficiency;

3. Cold forgings have good strength properties, because cold deformation will produce work hardening, thereby improving performance;

4. Precision machining is a precision molding process;

5. The cold forging process continues to develop.

Disadvantage of Cold Forging Aluminum Parts

1. The mold requirements are high, the mold is difficult to process, the price is high, and the processing time is long;

2. Not suitable for small batch production;

3. The material requirements are higher. Softening annealing treatment or surface weathering lubrication treatment is usually required: this is because the deformation resistance of cold forging is large.

Application of Cold Forging Aluminum Parts

RUIYU Aluminum can provide customers with cold forged products such as automotive parts, medical aluminum cans, and outdoor packaging products. Welcome to customize with pictures.

Cold Forging Chemical & Medicine

Cold Forging Electronics Parts

Cold Forging Food & Beverage Parts

Cold Forging Automotive Parts

T/T and L/C at sight are recommended. Product name:Custom Aluminum Extrusion Mold Fee:Full pay before mass production. Order:30% deposit,70% balance before delivery or L/C at sight. Other Situation:Please feel free to contact us....more