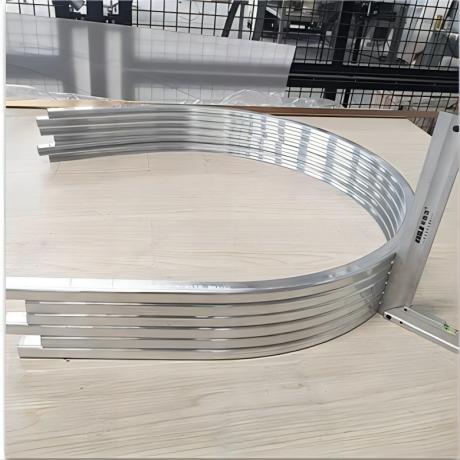

Aluminum Profile Bending Service

Aluminum profiles have advantages such as lightweight, corrosion resistance, and ease of processing. Among them, the bending process of aluminum profiles is an important processing technology, which can enable aluminum profiles to obtain curves of various shapes and angles without changing their physical properties.

Aluminum profile bending is a process of using mechanical force to bend aluminum profiles into the desired shape. It can bend aluminum profiles into various shapes such as arcs, ellipses, U-shapes, L-shapes, etc. to meet different design requirements.

1. Bending machine: According to the size of the aluminum profile, the bending machine with appropriate bending force is selected.

2. Bending die: According to the shape of the aluminum profile, the appropriate bending die is selected.

3. Bending angle: According to the bending angle of the aluminum profile, the appropriate bending angle is selected.

4. Bending process: According to the bending process of the aluminum profile, the appropriate bending process is selected.

5. Bending inspection: After the bending process is completed, the bending quality is inspected.

Bending process of aluminum profiles:

1.Preparation of aluminum profiles

2.Determination of bending angle

3.Making bending molds

4.Performing bending

5.Cooling treatment

The bending process of aluminum profiles can achieve curves of various shapes and angles, thus meeting different design requirements.

Bending machine display

The aluminum profile bending process can provide reasonable sizing allowance for parts, improve their manufacturing accuracy, and reduce their manufacturing costs. Stretch bending refers to the forming process of a profile pressed into a mold groove under the combined action of bending moment and longitudinal tension. Aluminum profile bending is an important forming process in industrial production, used to manufacture variable curvature extrusion and plate bending profiles with large dimensions, high requirements for shape accuracy, and large relative bending radii.

Aluminum profiles are a common building material with advantages such as lightweight, corrosion resistance, and ease of processing Point, therefore, has been widely used in fields such as construction, transportation, electronics, etc. Addition of aluminum profiles the bending of aluminum profiles is an important process in the construction process, which can make aluminum profiles better adapt to the shape and needs of the building.

Roll bending refers to the bending process of aluminum profiles by placing them on rollers and rotating them. This method is suitable for situations where the bending angle of aluminum profiles is small, and can quickly and efficiently complete the bending process of aluminum profiles.

T/T and L/C at sight are recommended. Product name:Custom Aluminum Extrusion Mold Fee:Full pay before mass production. Order:30% deposit,70% balance before delivery or L/C at sight. Other Situation:Please feel free to contact us....more