Automotive Aluminum Extrusions

High-Quality Aluminum Profiles From Asia: Made For The Auto Industry

Nowadays, automotive aluminum extrusion profiles are used more and more widely in new energy vehicles. The requirements for high-performance aluminum extrusion profiles for vehicles are: the strength is getting higher and higher, the mold is getting more complex, and the wall thickness is getting thinner. Aluminum profiles have a range of excellent features and in many cases have replaced high-strength steel in body structures. At Ruiyu Aluminum, we have the ability to provide automotive industry companies with the aluminum extrusions they need.

Factory Equipment And Technical Strength

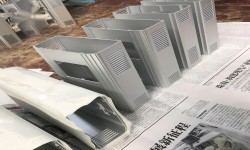

Our aluminum profile factory has advanced production equipment and superb technology to provide high-quality aluminum profile products for the automobile manufacturing industry. Our automotive aluminum profiles have been widely used in major automobile brands in China, and we have established long-term cooperative relationships with many well-known companies.

Manufacturing Service Scope

In addition to extrusion services, we offer a wide range of manufacturing options. Extrusions can be finished to your liking, whether powder coated, anodized or simply sanded. Your extrusions can be machined, drilled, cut, or stamped to suit your project needs.

On-Time Delivery, Trustworthy

We are well aware of the importance of on-time delivery to our customers, so we strictly control the production process to ensure that each batch of products can be delivered on time. Authentic manufacturers help ensure your extrusion quality, smooth communication and delivery time.

Get The Profile You Need For Your Application

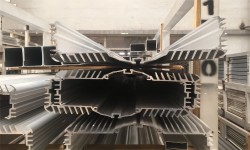

Aluminum extrusions for automobiles mainly use 6000 series aluminum alloys, such as 6061, 6063, etc., which have lightweight, high strength and corrosion resistance properties. In the past, aluminum extrusions were mainly used in structural parts such as car seats and frames. Nowadays, with the advancement of technology and the demand for energy conservation and emission reduction, aluminum extrusions have been widely used in key components such as automobile bodies, chassis, and suspension systems, injecting new vitality into the development of the automobile industry.

|  | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Automotive Aluminum Extrusion Components

Welcome to enjoy our product example pictures. The following shows you the practical application of the automotive aluminum extrusions produced by our factory. Through these pictures, you can more intuitively understand how our products contribute to the automotive manufacturing industry.

|  |  |  |

| Automotive Extrusion Casing | Automotive Extrusion Housing | Apron Tube | Automotive Extrusion Housing |

|  |  |  |

| Radiator Support | Crash Management Systems | Apron Tube | Electric Vehicle Charging Pile Shell |

Top-Class Extrusion Factory From China

As a professional aluminum extrusion manufacturer, Ruiyu Aluminum has a wealth of blank shapes and customized extrusion capabilities, and can provide you with the profiles you need for your project. Whatever your project needs, we can provide you with the right aluminum extrusion solution. We always adhere to customer-centricity and strive to provide customers with high-quality products and services. You are welcome to contact us at any time and let us work together to create more value for your project.

|  |  |  |

Custom Extrusion Capabilities

We do not have extrusions in stock, all extrusions are made to order. This means you can specify your exact requirements and our extruders are supplied with a range of alloying, tempering, finishing and other ancillary services. Contact us for more details and to discuss your specific extrusion requirements.

|  |  |  |

| Dies&Tooling For custom aluminum extrusion projects, molds are machined from H13 steel. Profiles can be stretched to 400mm (15 3/4") depending on shape, size and CCD. Mold costs typically range from $800 to $1600, with extrusion lead times of 1-2 weeks. | Alloys and Tempering Depending on your project needs, the appropriate alloy can be selected to obtain the required strength, corrosion resistance, and other properties. Usually 6000 series alloys are chosen. | Surface Treatment The choice of surface finish will affect the appearance and corrosion resistance of the profile. We offer a variety of surface treatments, including anodizing, powder coating and wood grain sublimation, so you can achieve the look you want. | Manufacturing Services Once extrusion is complete, your extruded aluminum profile can enter the manufacturing stage. We provide ancillary services such as drilling, cutting and stamping that are both accurate and affordable. This will save you the time and cost of performing these operations during the installation phase. |