6063 Aluminum: Get to Know its Properties and Uses

Alloy selection plays an important role in your aluminum extrusion project.

The history of 6063 aluminum alloy can be traced back to the early 20th century, when aluminum began to be widely used in various industries as a lightweight and high-strength metal. As the construction industry's requirements for appearance and performance continue to increase, people have begun to research and develop various aluminum alloys to meet market needs.

6063 extruded aluminum is the most popular aluminum extrusion alloy, so this is a natural consideration. 6063 extruded aluminum is widely used in construction. Therefore, it is often called architectural aluminum.

It is a medium strength alloy used in railings, window frames, door frames, roofs, railings, sign frames, store fittings, irrigation pipes, building products, electrical, marine, plumbing, recreational equipment, storage tanks, truck frames and trailers and other applications.

|  |  |  |

Today, 6063 aluminum extrusion alloy is still developing, through new processes and technological innovations, to adapt to more stringent construction requirements and environmental protection standards.

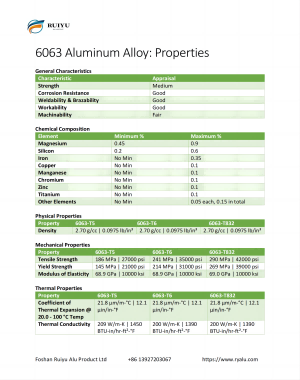

Here are Some General Characteristics of 6063

6063 extruded aluminum alloy improves the processing performance and mechanical strength of pure aluminum by adding silicon and magnesium, while maintaining good weldability and corrosion resistance. At the same time, it is also quite workable. Download a PDF about its properties and material properties.

| Characteristic | Appraisal |

| Strength | Medium |

| Corrosion Resistance | Good |

| Weldability & Brazability | Good |

| Workability | Good |

| Machinability | Fair |

By tempering this alloy, greater strength can be achieved.

6063-T5, 6063-T6, 6063-T832 Aluminum Material Properties

Some of the most common tempering options for 6063 extruded aluminum alloy are T5, T6, and T832.

Physical Properties of 6063 Aluminum Extrusion

Here we can see the density of the 6063 aluminum extrusion.

| Property | 6063-T5 | 6063-T6 | 6063-T832 |

| Density | 2.70 g/cc | 0.0975 lb/in³ | 2.70 g/cc | 0.0975 lb/in³ | 2.70 g/cc | 0.0975 lb/in³ |

Note that there is no difference in density between T5, T6 and T832 tempers.

Mechanical Properties of 6063 Aluminum Extrusion

Here we can see the tensile strength, yield strength and elastic modulus for T4 and T6 tempers.

| Property | 6063-T5 | 6063-T6 | 6063-T832 |

| Tensile Strength | 186 MPa | 27000 psi | 241 MPa | 35000 psi | 290 MPa | 42000 psi |

| Yield Strength | 145 MPa | 21000 psi | 214 MPa | 31000 psi | 269 MPa | 39000 psi |

| Modulus of Elasticity | 68.9 GPa | 10000 ksi | 68.9 GPa | 10000 ksi | 69.0 GPa | 10000 ksi |

Thermal Properties of 6063 Aluminum Extrusion

Here we can see some of the thermal properties of the 6063 extruded aluminum, including coefficient of thermal expansion and thermal conductivity. Includes T5, T6 and T832 tempers.

| Property | 6063-T5 | 6063-T6 | 6063-T832 |

| Coefficient of Thermal Expansion @ 20.0 - 100℃ Temp | 21.8 μm/m-°C | 12.1 μin/in-°F | 21.8 μm/m-°C | 12.1 μin/in-°F | 21.8 μm/m-°C | 12.1 μin/in-°F |

| Thermal Conductivity | 209 W/m-K | 1450 BTU-in/hr-ft²-°F | 200 W/m-K | 1390 BTU-in/hr-ft²-°F | 200 W/m-K | 1390 BTU-in/hr-ft²-°F |

NOTE: The material properties above are extracted from Matweb, here , here and here . Please note that they cannot be 100% verified.

Chemical Composition of 6063 Aluminum Extrusion

6063 aluminum extrusion is part of the 6000 series alloys. Therefore, its main alloying elements are magnesium and silicon. Magnesium is added to increase strength, while silicon is added to lower the metal's melting temperature. Here we can see a guide to the chemical composition of 6063 Aluminum Extrusion.

| Element | Minimum | Maximum |

| Mg | 0.45 | 0.9 |

| Si | 0.2 | 0.6 |

| Fe | No Min | 0.35 |

| Cu | No Min | 0.1 |

| Mn | No Min | 0.1 |

| Cr | No Min | 0.1 |

| Zn | No Min | 0.1 |

| Ti | 0.0 | 0.1 |

| Other Elements | No Min | 0.05 each 0.15 in total |

Now that we understand the chemical composition of 6063 aluminum extrusion, let's talk about how 6063 aluminum extrusion compares to some other key options.

Compare 6063 Aluminum Extrusion to Other Alloys

Alloy 6063 is the most common alloy for extrusion, but you may be considering other options for your specific application. Here are some other common alloys that are often considered alternatives.

6063 vs 6061

| These two alloys are the most popular in extrusion, with 6063 in first place and 6061 aluminum in second. Both belong to the 6000 series and are primarily alloyed with magnesium and silicon. Therefore, they share many similar properties. They have similar corrosion resistance, weldability and processability, making them suitable for many different applications. |  |

But 6061 aluminum extrusion is the stronger of the two, roughly equal in strength to structural steel when tempered in T6. Therefore, it is often used in structural applications requiring higher strength and toughness. The 6063 aluminum extrusion has advantages in the construction and decoration fields because of its excellent formability, which makes it easier to form profiles with complex shapes and smooth surfaces. 6063 aluminum extrusion is also very suitable for anodizing and provides better corrosion resistance Learn more »

Summary

6063 aluminum extrusion is favored for its excellent extrusion properties, high corrosion resistance, and ability to create complex shapes, making it the material of choice for extruded profiles. Not only does it look beautiful, but it is also strong enough to be used in construction.

If you need more detailed information, we provide PDF document on 6063 aluminum properties for your reference, so that you can have a more comprehensive understanding of this material.

Welcome to our Aluminum Extrusions page to learn what kind of service and support we can provide you.

Download 6063 Aluminum Properties PDF

General characteristics, properties, and chemical composition of 6063 aluminum.

![]() 6063-Aluminum-Alloy-Properties.pdf

6063-Aluminum-Alloy-Properties.pdf